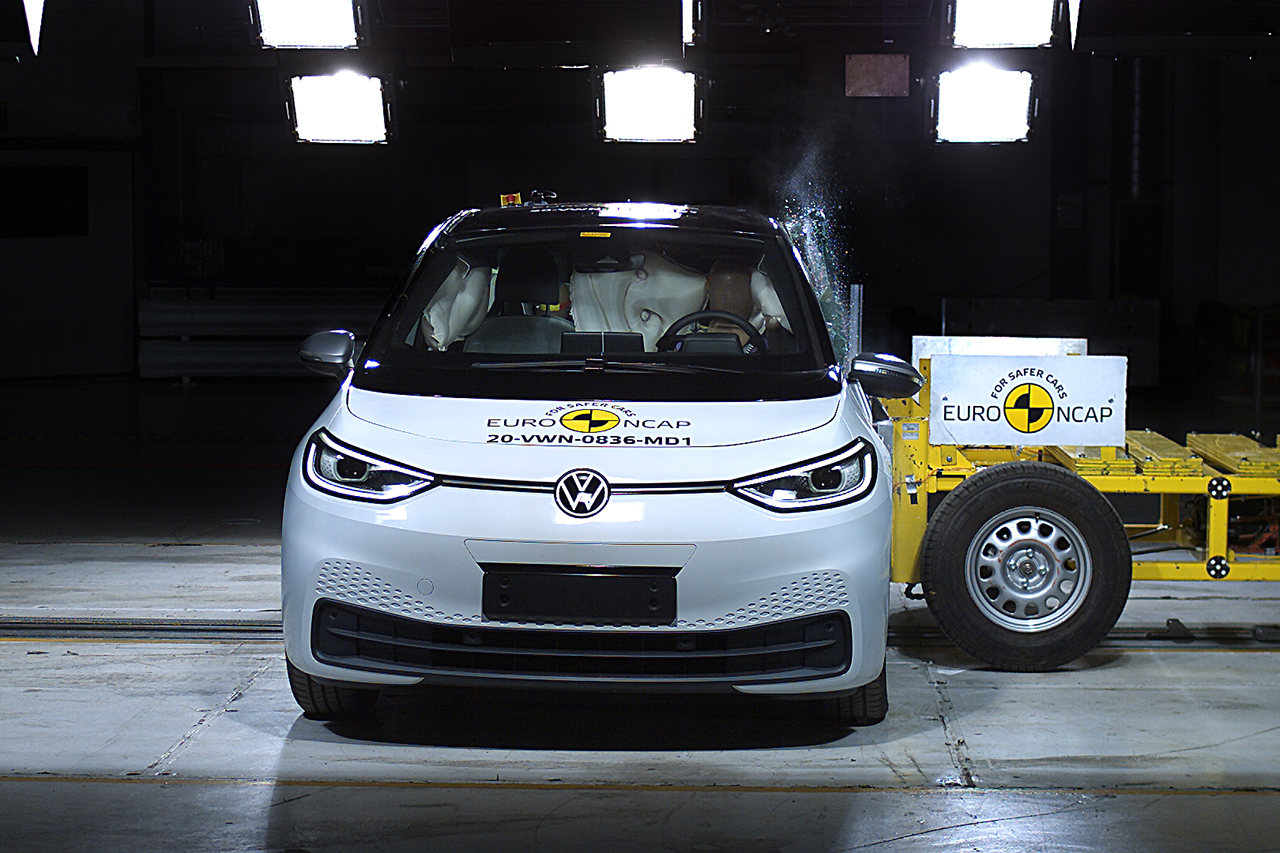

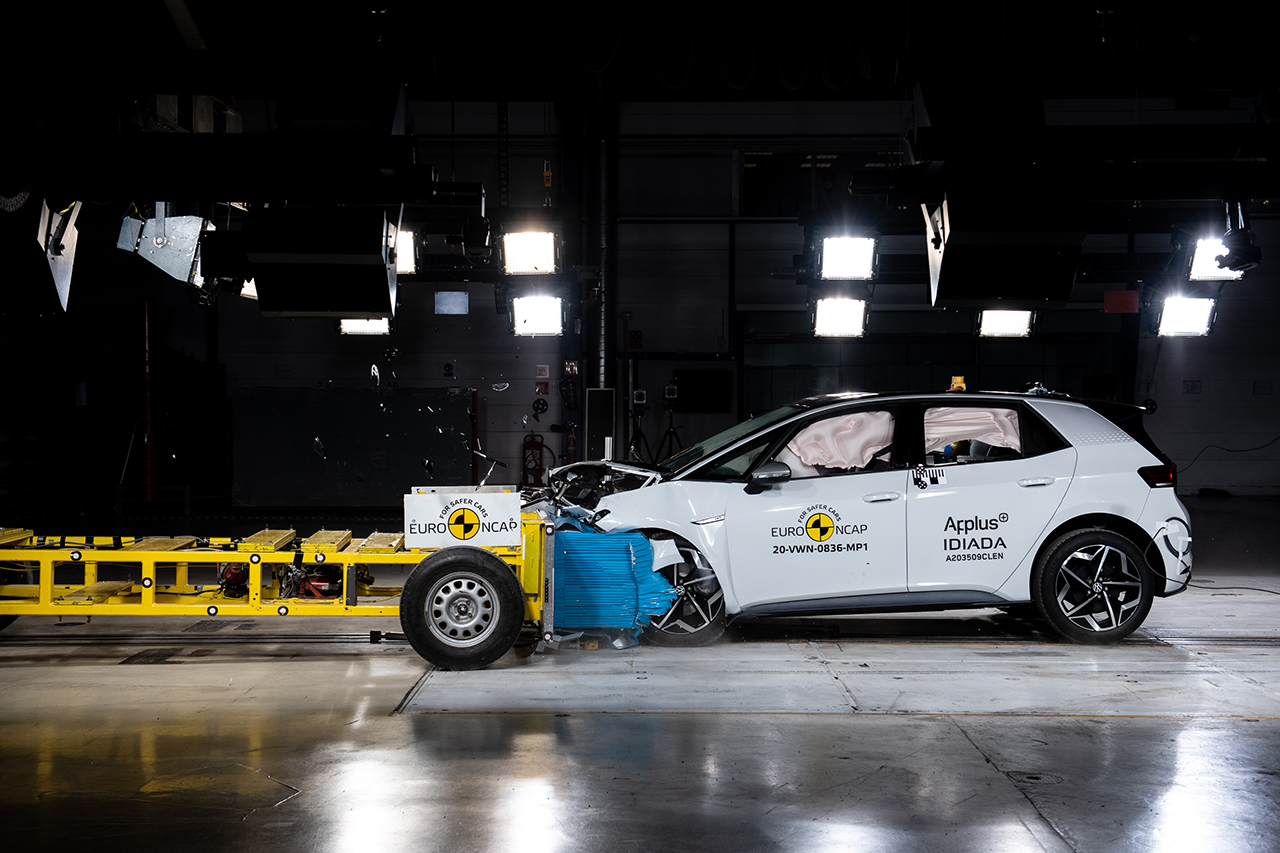

Volkswagen is counting on the continuous improvement of crash test simulations to change the way it tests the safety of its future models. Actual prototypes, sent against walls or other vehicles by EuroNCAP, would now be replaced by computer tests.

To market a vehicle, you must go through the crash-test box in order to prove its resistance and its level of safety. Besides theEuroNCAP, the referent body in Europe, manufacturers also carry out their own tests. According to Volkswagen, these could soon be replaced by computer simulations.

Vehicles tested on computer mainly?

Markus Biewendt, responsible for vehicle safety at Volkswagen, has indeed claimed that much progress has been made on the digitization of tests. The results of these tests are more and more reliable, and very close to those of the usual physical crash tests. Thus, the analyzes make it possible to predict certain reactions or to confirm hypotheses before passing the model to scale 1 to the test. Because, these tests are very expensive.

Simulations can now incorporate more complex cases, Biewendt says, and there will soon be no need for prototypes sent up against walls. ” Our goal is to eliminate any kind of hardware testing during development. (for example, up to the level of the airbag module) », He explained to our colleagues from Automotive Testing Technology International, in order to keep the prototypes only for the final homologation process.

Reduce development time and costs

Thanks to the digitization of tests, Volkswagen could save time on vehicle design and reduce development cost. Indeed, physical crash tests have a significant cost (raw materials, manufacture of the prototype, dismantling for analysis, potential destruction) that computer simulation can partially avoid. On the other hand, it is not certain that the actual tests will be abandoned for all that. It happens that some vehicles create a surprise like the Volkswagen Golf 8 whose rear door opened during a crash test!