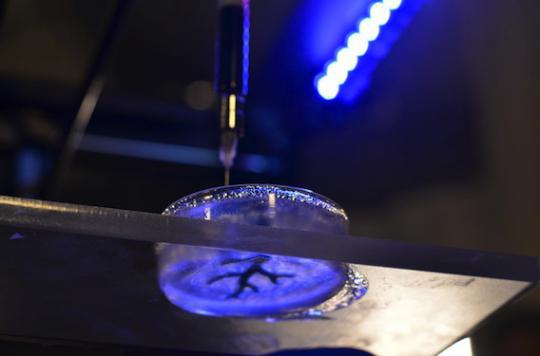

American researchers have successfully bioprinted 3D models of the heart, femur and coronary arteries from soft materials.

Skin, ear, heart… 3D printing is no longer limited to plastic or metal objects. Tomorrow, this technology will be able to manufacture human tissues or even entire organs. An answer to the organ shortage, an alternative to animal testing, bioprinting gives rise to hope and is constantly reinventing itself.

And for good reason. A research team from Carnegie Mellon University (Pittsburgh, United States) featured in the prestigious journal Science Advances a new method for printing structures in soft materials. Until now, 3D printing required a robust support in which the printer deposits the cells layer after layer, according to a predefined computer architecture. This support serves as a skeleton for the cells to give shape to the tissue.

“The challenge with soft materials – imagine jelly – is that they collapse under their own weight,” says Adam Feinberg, study leader and professor in the Department of Biomedical Engineering at Carnegie Mellon.

An inexpensive technique

To overcome this difficulty, engineers have developed a clever technique: soft tissues containing collagen and other biological fibers are printed in a hydrogel support. The printed structure is then recovered by melting the support (as can be seen in the video). This technique thus makes it possible to obtain the bio-printed fabric without damaging the structure and the cells it contains.

.