This innovative technique could provide relief from conductive hearing loss: when a person loses their hearing after infection, trauma or birth defects.

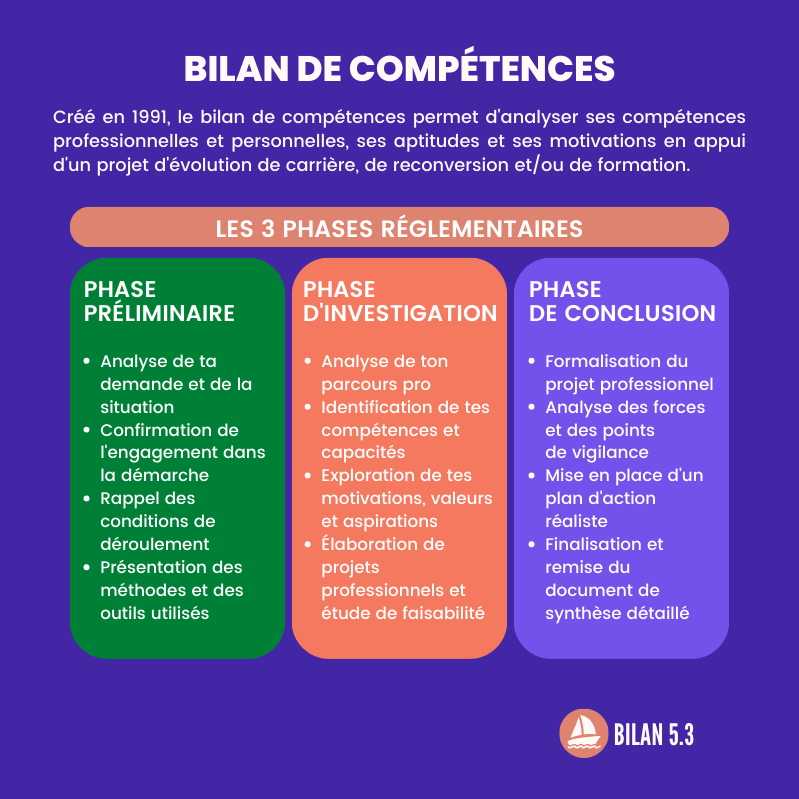

They are the smallest bones in the human body and man is now able to replace them: the hammer, the anvil and the stirrup are three ossicles that make up the middle ear. South African researchers have succeeded in manufacturing them using 3D printing and then grafting them. This world premiere is recounted in a communicated from the University of Pretoria.

Three people already transplanted

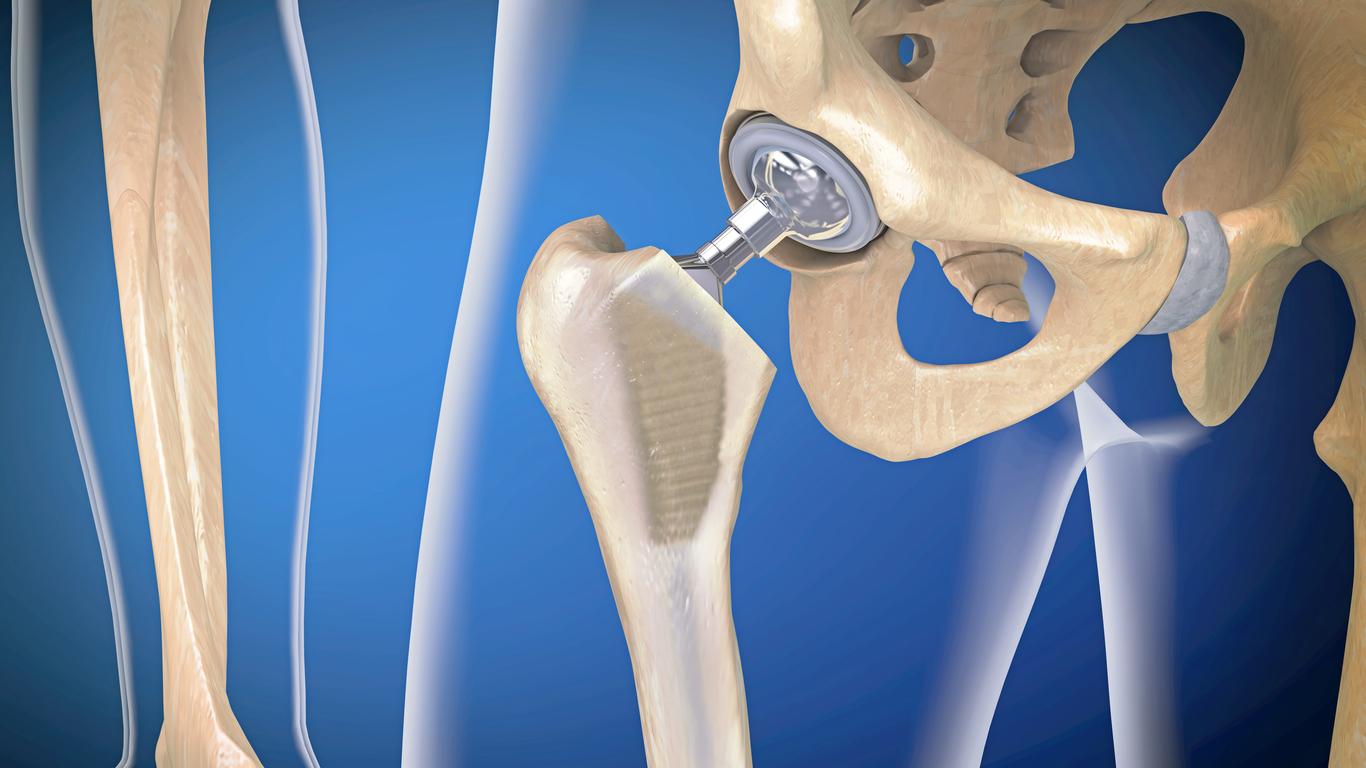

“3D allows us to do things that we never thought we could do,” rejoices Professor Mashudu Tshifularo, who led the three transplants. Three patients were able to benefit from this innovative technique, including a person who lost his hearing after a car accident. According to the researchers, it would be possible to use this method in newborns. “This procedure is less risky than prostheses, and the surgical processes associated with it”, specifies the researcher. After printing the bones using 3D technology, the researchers graft them with an endoscope, to avoid unnecessary scarring.

A solution to conductive hearing loss

The middle ear is located between the outer ear and the inner ear: when the outer ear picks up sound waves, it vibrates the eardrum, which in this movement, moves the ossicles of the middle ear. These carry the sound waves to the inner ear. Some people suffer from conductive hearing loss, a disorder of the middle ear. Several factors can explain it: congenital disease, trauma, infection or metabolic disease. According to South African scientists, this new technique could be a solution for patients who are victims.

This 3D printing technique is only in its infancy. Today, Professor Tshifularo calls for fundraising to be able to develop his innovation as much as possible.

.