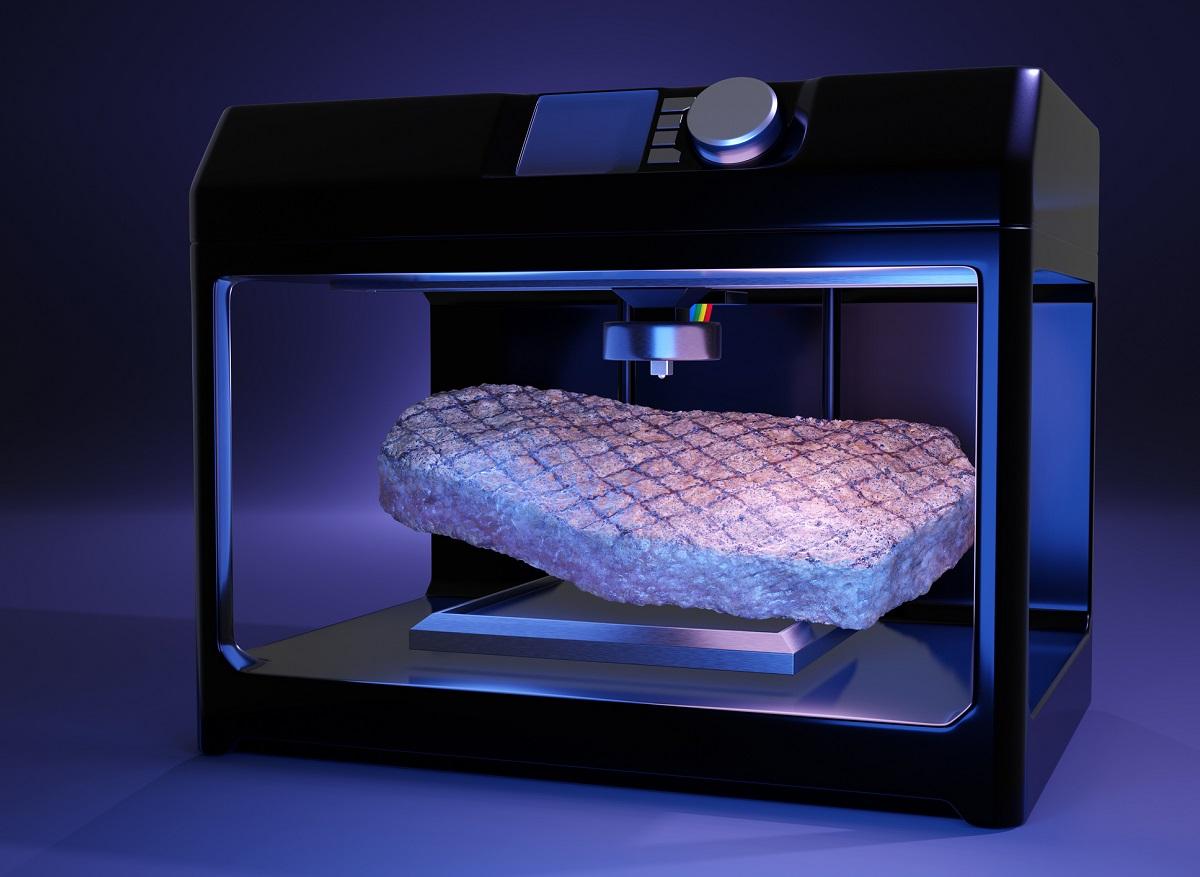

Scientists at Newcastle University have 3D printed a human cornea using stem cells.

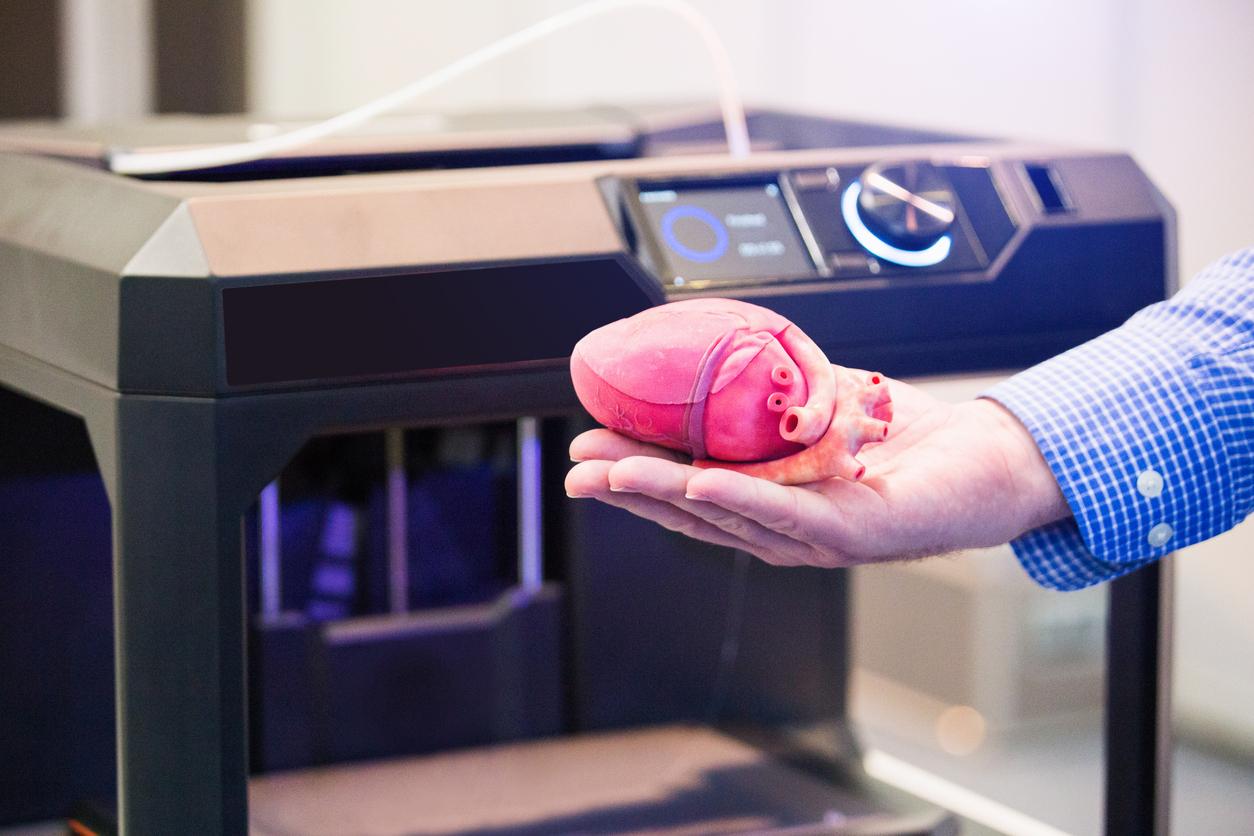

3D printing is part of the future of medicine. Whether it is a plaster cast, a prosthesis, or skin, this technique has shown its interest on numerous occasions. British researchers have just made a new breakthrough in the use of this technique. They managed to 3D print a cornea, made from human stem cells. Their research was conducted at the University of Newcastle, UK.

The cornea is a transparent tissue that covers the iris and the pupil. It is through it that the light passes which is then transmitted to the lens and to the retina. It can be damaged due to infection, trauma or inflammation, causing partial or complete blindness. Corneal transplants allow patients to regain proper vision. According to national union of ophthalmologists of France, each year, 8000 corneas would be necessary to cover the needs of the population.

Our scientists from @igmengagencl have used #stemcell technology to 3D print the world’s first human corneas ???? https://t.co/7fdCdwueM1 #impactNCL # 3dprinting #biomedicalengineering pic.twitter.com/Cf0q39TQDW

– Newcastle University (@StudentsNCL) May 30, 2018

10 minutes to print a cornea

British scientists used corneal stem cells from a healthy donor and mixed them with alginate and collagen. This mixture was used to create a “bio-ink”. This was then used in a 3D printer and made it possible to produce corneas.

Che Connon led this work and explains, “Our gel keeps stem cells alive while producing a material that is strong enough to hold its shape but flexible enough to pass through the mouthpiece of a 3D printer.” 3D technology also allows them to adapt the shape and size of the cornea to the patient’s eye. The printing process takes 10 minutes.

A widespread technology in the health sector

3D technology is used in many fields today. Handicap International, for example, uses it to equip amputees in disadvantaged areas. 19 patients were equipped with this device in 2016. Printing is done to measure and remotely. The only barrier remains the price: 1,200 euros against 70 with conventional methods.

Other researchers have succeeded in 3D printing cartilage, a very promising method because this tissue cannot regenerate itself. Printing of limb prostheses, tissues, or other, 3D printing continues to develop. In 2015, the healthcare 3D printing market was worth $ 490 million.

.