Plasan SandCat, the ideal daily driver

How does a fearless armored monster fare as everyday transport?

Stamford, Lincolnshire – the ‘prettiest Georgian town in England’, according to the sign – is probably where you least need the services of an armored car. At least if the local sewing party doesn’t start a modest revolt, and there isn’t a slightly sarcastic border dispute between the owners of two neighborhood apps. Well, at least the beige desert tones of the Plasan SandCat go well with the local honey-colored sandstone. It actually blends in better than you might think, despite the fact that it weighs a seven-and-a-half-ton, science-fiction-esque light armored tactical vehicle is. But we’re here anyway.

It seems a bit odd, shimmying around a sleepy market town to this degree of overkill, but I’m gently wringing this behemoth into my daily schedule to see if it can handle the mundane as well, rather than just more spectacular performances. . That’s why I went to the supermarket, to the gym, I got some dog food, I filled it with diesel (which was definitely not an everyday thing for my wallet, with 135 litres…), I commuted, stopped by the pub drove for my mid-morning cup of tea, and pretty much did all the things I normally would. The most rational question here is simply: why? The completely irrational answer is: because here you are looking at the future of the car.

Sounds ridiculous, doesn’t it?

A normal car has nothing to do with something ridiculously big like this, a vehicle that can handle the most terrible thing the world can throw at it, in some cases literally, and at bullet speed. But while a Ford Fiesta doesn’t come with options like a remote-controlled 12.7-millimeter Browning machine gun, extra GPK (‘Gunner Protection Kit’ – protection for the gunner) for the hatch in the roof (which is officially a ‘dome’). ‘ hot) and six ‘universal gun ports’, from which you can, er…universal, fire, the SandCat isn’t as intimidating as it all sounds from behind the wheel.

Well, he may have doors heavy enough to cut your fingers off if you get them between them when slamming shut, windows thick enough to return bullets from light firearms, be 6 meters long, over 2.3 meters wide and more than 2.5 meters high, and it may have a turning circle of 16.6 meters – but then you really only care about size. And it is best to get used to it. Sure, you may have some concerns about parking.

Not the most agile car

Certainly with blind spots that France fits into with some ease, and despite the supermodel-sleek side windows that give you a more panoramic view than you might think, and the fact that a reversing camera is available as standard. No, it’s not the most manoeuvrable car in the parking lot of my pub, the Bertie Arms, but on its own the SandCat drives a lot like a Ford Transit that is extremely loaded. With lead tiles. They are packed in uranium. Anyway, it’s not the physical dimensions of the SandCat that interest us right now. Of course, we’re more concerned with the principles surrounding its design and construction, which may have major implications for the future of the car you drive today. And then it mainly comes down to the materials your car will be made of, and how it will be put together.

So, what does this intimidating SandCat have to do with real life?

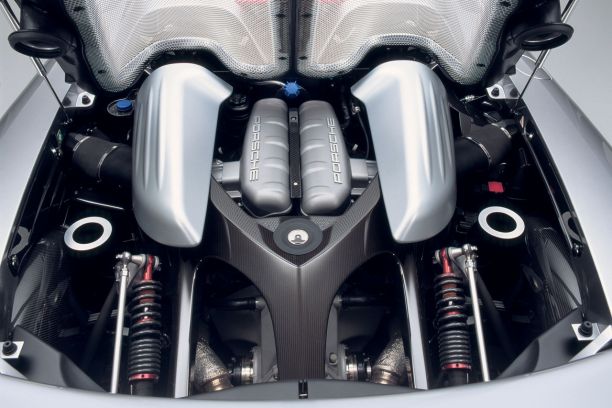

Well, the SandCat is based on the chassis of an American heavy duty Ford F-Series pickup, but chassis and powertrain aren’t the most important here. Let’s face it: a 6.75-litre diesel with 335 hp and 983 Nm is nice, but not exactly a marvel of technology. No, it’s more about what’s on it. And to explain that, we turn to a gentleman named Nir Kahn, the man who designed it and someone who has some very interesting ideas about how armored cars could affect the car you drive in 2030.

“Historically, heavily armored cars have always been large welded steel boxes, while the lighter ones simply had armor panels screwed into or against the regular, thin-metal bodies of Jeeps or Humvees, or ‘regular’ civilian cars,” says Nir.

This SandCat is glued

“One of the innovations we’ve made on the SandCat is what we call the ‘glued hull’. In essence, we do not use an armored welded steel box, but the body is assembled from all kinds of different plates. This also allows us to use dissimilar materials – including composites [materialen die zijn opgebouwd uit verschillende componenten] – and we can make the parts and body assembly cost-effectively, in relatively large quantities.

So instead of adding armor to a vehicle, we build the vehicle from that armour, often made up of layers of metal, composites and, for the higher levels of protection, also ceramic materials. This way we are not limited by the pre-existing geometry of a stripped vehicle and we can already start saving weight during the design process, optimizing angles and surfaces to get the best result from the materials. In doing so, you keep costs lower, the ergonomics improve and, icing on the cake: you can make them look even better. Or well, at the very least you can give them an aesthetic suitable for their task.’

That all sounds perfectly reasonable

You build an armored car from the armor itself, rather than adding armor in or to an existing silhouette. Pack it and you can put it in boxes and transport it very efficiently to anywhere in the world you need it. Make the parts interchangeable – so you can replace them if they’re damaged – and you’ve got an armored car that’s lighter, stronger and easier to repair. And that’s where it suddenly starts to become hugely relevant to stuff that we might come across on the street.

Nir again: ‘The idea may seem simple or obvious – building armored cars like an Ikea cabinet – but implementing it requires a lot of hyper-advanced simulation and analysis, and a lot of rather destructive testing. These cars must be able to withstand a landmine. And so we literally blow up vehicles, with crash test dummies in them, measure the accelerations and forces exerted on occupants – it’s like NCAP, only more violent.’

Is the SandCat good as daily transport?

So if you add up all the different qualities of our SandCat, which we are now happily fiddling with Stamford, its symbolism becomes clear: what do we need, in an everyday car? A light, rigid, efficient, multi-component and repairable architecture that is also great at bouncing things off. Like any other car. Or a lamppost. Or a wall. If there are “crumple zones” that can handle an explosion, that could be useful in a more mundane collision. And if that does happen, the modular approach of the whole could mean that you only have to replace or repair small parts, which could also reduce insurance premiums. Sounds strange, but it’s already happening.

‘Passenger cars are already undergoing a similar design change. After a century of welded steel monocoques, many ordinary cars are also made with different materials, steel and aluminum are mixed with alternatives as composites, and are joined with other mechanical connections such as rivets. The lessons learned from the behavior of composites when exposed to explosions are also applied to ensure that new, lightweight car bodies can survive collisions. And so you can save lives, save weight and do it all cheaper, in one almost literal blow.

Does that sound familiar?

That’s because just about every sports car builder is doing the same thing right now, albeit with a little less focus on survivability in mines or RPGs. But it’s not just about the knowledge of materials and the efficiency that would get a little bit – the way cars look could also undergo a fundamental change. Because if you unleash a revolution on the skeleton, everything attached to it changes too, doesn’t it?

‘One day we’ll all drive to the supermarket with a son-of-SandCat’

‘In order to use composites in a smart, cheaper way, we will have to think differently about how we design cars. And yes, that means a lot of challenges, including those related to aesthetics. Cars shine and are beautifully painted because they are made of pressed metal. But if that’s not what they’re made of, why should they look like that? Changing that will be a slow process, but if we transfer this kind of technology to passenger cars, they will become safer, lighter and more fuel efficient.

The bottom line: the SandCat is a revolution

What we see here is the possibility of a revolution from an unexpected quarter. Forget all those little technological changes that trickle down to us from motorsport. The design and construction of a modern armored car could have more of an effect on the car you drive in the future than something like an F1 car. From the way the car is made to the materials from which.

A strong structure helps the dynamics, gives the suspension a solid foundation to do its job. It helps in collisions, both in terms of impact and the way airbags can function. A lighter skeleton will also make the engine more efficient, both in terms of consumption and speed, and lightness only brings more lightness. A lighter car needs smaller brakes and tires, less cooling, less of everything. And if you change the manufacturing process, you get more design freedom; cars can become more aerodynamic, take on more complex shapes, and be less dependent on the restrictions imposed by their materials.

Which leads me to the inevitable conclusion that one day we’ll all be driving a son-of-SandCat to the grocery store one way or the other. I just hope I can still have one with a gun turret.