Cartilage does not regenerate. But researchers have managed to 3D print it to repair worn joints.

Print three-dimensional cartilage. This is what the American professor Ibrahim Ozbolat and his team succeeded in doing. Cartilage is a rigid tissue that makes up the joints. It can wear out or deteriorate but is not able to regenerate itself. Once damaged, in people with osteoarthritis for example, it remains damaged with no possibility of improvement. The challenge is therefore not to repair but to recreate new cartilage.

Several attempts had succeeded in growing cartilage cells in a hydrogel composed of 90% water, but the result was of poor quality. Cells could not communicate with healthy tissue, and if dehydrated, the hydrogel could produce toxic compounds.

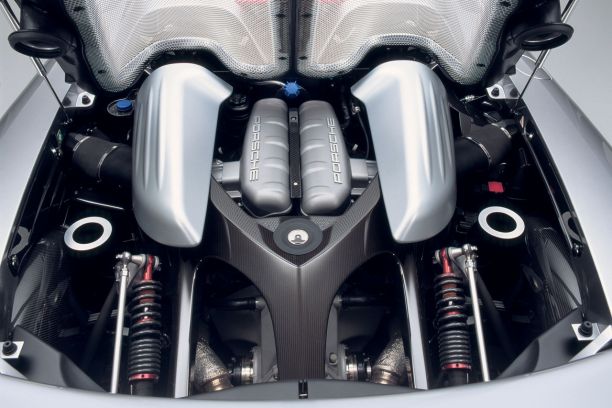

Image credit Ozbolat, Penn State

From algae to self-adhesive patch

This time, the researchers proceeded differently. They injected cartilage cells into a small tube made of alginate, a kind of seaweed. The cells grow for a week and clump together without sticking to the wall of the tube. This material thus created replaces the ink of 3D printers thanks to a special nozzle. In half an hour, the machine prints a sufficiently consistent and self-adhesive patch to continue growing in a Petri dish, in a nutrient medium.

The advantage of this technique is that it produces larger tissue than before without the need for scaffolding. 3D also reproduces the natural architecture of cartilage with alternating vertical and horizontal printing.

The properties obtained by this method do not yet compete with natural cartilage but are much better than hydrogel cultivation. “Each individual will have to provide cells of his own cartilage or stem cells differentiated into cartilage cells to avoid the risk of rejection,” says Dr. Ozbolat. This device will thus make it possible to create large patches of cartilage to treat worn joints, bringing hope in particular to the millions of people suffering from osteoarthritis in France.

.