The aerodynamic engineers of the F1 Alpine team are now helping to develop the brand’s road vehicles. The next Alpines will be all electric, and their aerodynamic performance will have a major impact on their range.

Aerodynamics, which have always been crucial for reducing vehicle fuel consumption as much as possible while contributing to their performance, takes on even greater importance in the era of the all-electric switchover. Because the battery of a “zero emission” car does not yet offer as much autonomy as the tank of its thermal equivalent, and the time required to recharge it makes this handicap a double penalty. This autonomy becomes one of the sinews of war between manufacturers. So to optimize the development of its future models, which will all be electric, Alpine is now calling on the aerodynamicists and infrastructure of its F1 team.

From one wind tunnel to another

Alpine has its headquarters in Les Ulis in Essonne, its factory in Dieppe in Seine-Maritime, and the Renault group generally uses the S2A wind tunnel installed in Montigny-le-Bretonneux for its road vehicles in the Yvelines, an installation which it shares the management with its competitor PSA (now integrated into Stellantis) as well as the CNAM (Conservatoire National des Arts et Métiers). However, the Alpine team has a technical center in Enstone, England, responsible in particular for the development of the chassis of its single-seaters, with an exclusive wind tunnel and therefore dedicated equipment and personnel. F1 requires, the level of equipment and skill is among the highest in the automotive industry.

It has been two years now that these assets have been used to develop the Alpine road bikes. ” We set up our collaboration in March 2020 and we take stock every week to optimize our methodology, our CFD tools (computer simulation of fluid dynamics, editor’s note) and apply Formula 1 methods during our tests “says Pierre Sancinéna, aerodynamic engineer on the production Alpine.

TO READ. Renault’s Enstone plant: at the heart of the Formula 1 factory

F1 know-how on the road

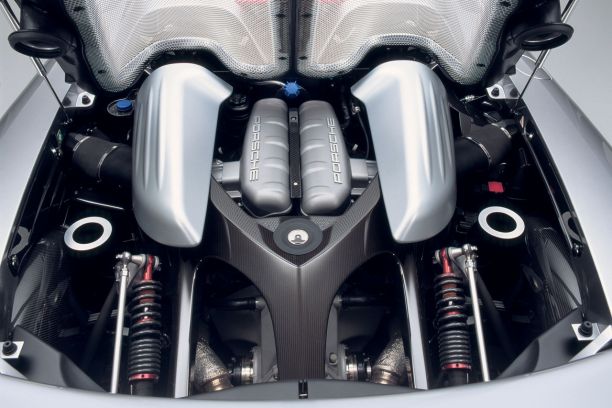

In the spring of 2021, while Alpine was putting the finishing touches on the restyled A110, a copy of the berlinetta was sent to Enstone. It was equipped with a set of air pressure sensors close to the Pitot tubes used in aviation, mounted on a metal mesh nicknamed “rake” (rake) in English, like an F1. Back in France, the car was measured in a wind tunnel equipped in this way. It was also coated with a special paint used by F1 engineers in their tunnel. And the latter collaborated with their colleagues from France to analyze the images and results obtained.

Enstone staff are now working on future electric Alpines. ” The group working on the aerodynamics of the A522 has just completed a particular project for the road branch of Alpine, and we are preparing to launch another. “, Matt Harman, new technical director of Alpine in F1, recently revealed to the British journalists ofCoach. And to add: We are strengthening the links between these two teams, both for physical tests and computer simulations. (…) They really enjoy working on these projects, so it will continue. In fact, we’ll probably apply more of our engineering expertise to road cars. »

Electric SUV and city car to start

The links between Alpine road and F1 could therefore go beyond aerodynamics, and relate in particular to electrification technologies. Laurent Rossi, Managing Director of Alpine, said: ” We’re transferring battery management technology, because whether it’s an F1 hybrid or an electric car on the street, it’s exactly the same now. The two weeks of cessation of activities imposed on F1 teams in August (shutdown) should be used for the next production Alpines. The Enstone team is probably putting in the work to develop the electric SUV announced under the name crossover GT (code DZ110), expected in 2025. The electric sports compact derived from the next Renault 5 will also pass through their handsbefore the turn comes of the replacement for the A110 co-developed with Lotus, which will offer a “cousin” bearing the code name Type 135 from 2026.