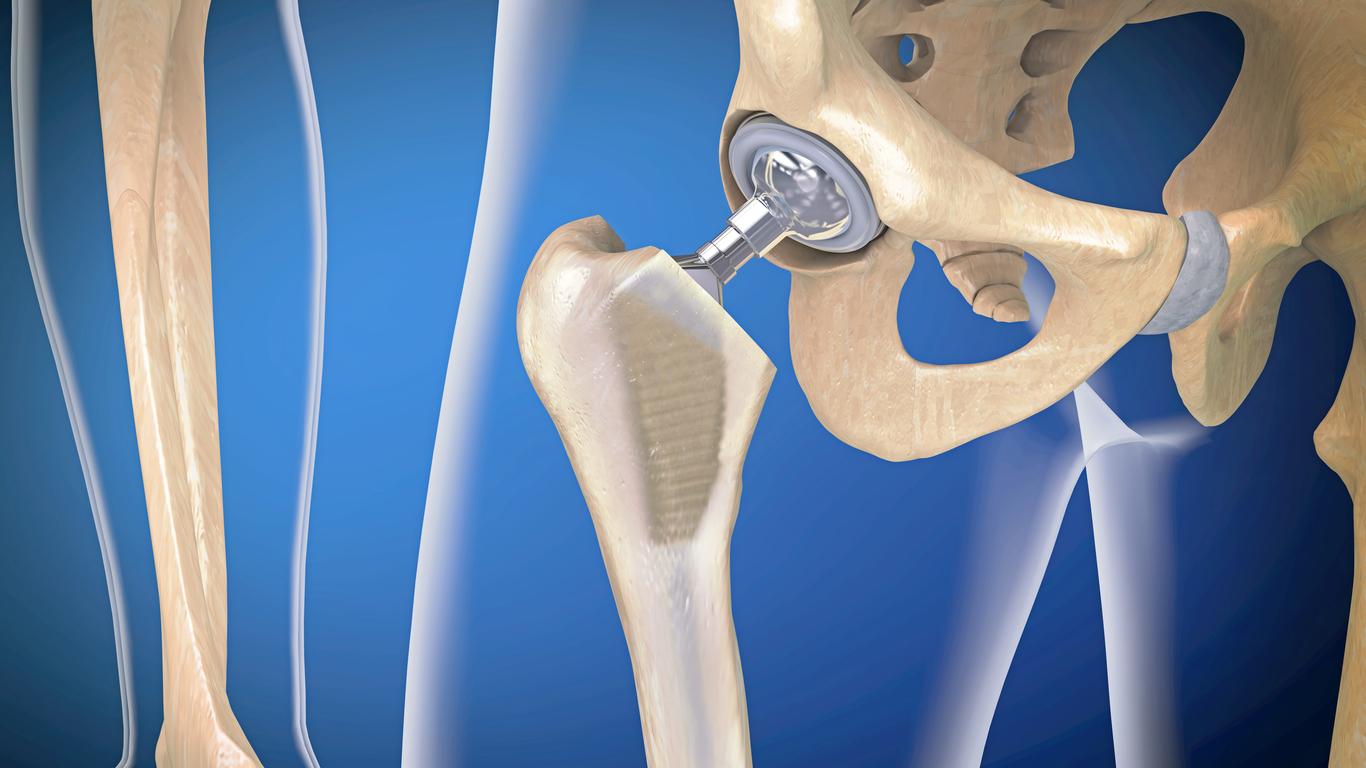

Handicap International has developed a system of 3D printed prostheses at a distance. A scanner allows molds to be made from remote areas.

It’s hard to imagine how difficult access to a prosthesis can be when you live in France. But in many disadvantaged countries, replacing an amputated leg is impossible. Between initial appointments, adjustment, monitoring, cost of the device … the medical course lengthens. For the most isolated populations, the question therefore does not arise. And life goes on without support.

Aware of these difficulties, Handicap International is making a gesture towards amputees. “In low-income countries, only 5 to 15% of people requiring orthopedic devices (…) can access this service”, underlines the NGO. His weapon to remedy this: 3D printing. Since 2015, the organization has been working on the development of customized and remotely printed prostheses. The trials, carried out in Togo, Syria and Madagascar, are rather conclusive.

Transportable technology

In 2016, 19 patients were fitted with 3D printed leg prostheses. This method considerably simplifies the treatment process. “Before, you had to make a plaster mold of the stump, go back four or five times to adjust it”, explains a spokesperson for Handicap International at theAFP. Then, the installation of a resin was necessary.

Thanks to 3D printing, only three steps are necessary. A small scanner makes it possible to create a digital mold, retouched by an orthopedic technician in order to respect the standards. The images are uploaded to the printer. The prosthesis is then sent to the care team, who then performs the placement.

The 9 months of tests have shown that the equipment complies with current requirements. The prosthesis is resistant and lasts. But the real argument in favor of this technology is the scanner. It can be stored in a bag, which makes it easier for teams to travel. The most isolated areas can be reached.

The question of cost

These results are conclusive. So much so that before the end of the year, Handicap Internationl has planned the installation of a printing center in Togo. And the NGO hopes to reach 200 poses by this date.

Isabelle Urseau, Rehabilitation Manager at Handicap International, does not hide her enthusiasm. “3D printing will change the way professionals work with patients and make it possible to better organize the services offered, for more efficiency,” she said in a press release.

But it will be necessary to solve a major problem: that of the price. The 3D printed prosthesis requires an expenditure of 1,200 euros, against 70 with other techniques. Speed has a cost which may prove to be excessive for the poorest. The NGO is aware of this problem, and has set about resolving it.

.